Why is the Glass Door of the Shower Room Fixed with an Explosion-Proof Film?

Dec 27, 2023

In recent years, the surge in reports about "shower room glass explosions" has left consumers questioning the safety and trustworthiness of inferior shower room products. The subconscious fear of stepping into what feels like a ticking time bomb has instilled skepticism and reluctance among consumers, making them wary of the very product designed to provide relaxation and comfort. As a result, many consumers, driven by safety concerns, opt to adorn the glass doors of their shower rooms with a protective layer – the shower room glass explosion-proof film. But how much do consumers really know about this safety-enhancing addition?

Why is Explosion-Proof Film Essential for Shower Rooms?

The phenomenon of shower room explosions often stems from the use of subpar tempered glass or even ordinary glass. While such glass boasts strong resistance to heat and cold, it is ill-suited for the humid and dynamic conditions within a shower room. Even with high-quality fully tempered glass, incidents of spontaneous breakage may occur due to various reasons, including manufacturing defects or external impacts.

Maintenance issues and improper usage by users can exacerbate the problem. Scratches from sharp objects can create micro-cracks, leading to eventual explosions. The national standard for tempered glass in shower rooms acknowledges a self-explosion rate of three in a thousand. While tempered glass undergoes safety treatments, the risk of self-explosion remains, posing a potential threat. The application of an explosion proof film, even in cases of film combustion, ensures that the film remains in place until safely removed, minimizing the risk of personal injury and enhancing protective performance.

Characteristics of Explosion-Proof Film for Shower Room Glass

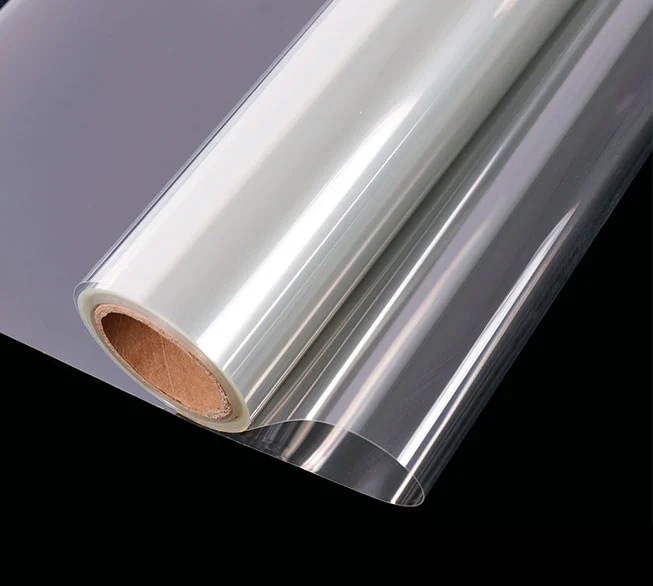

Shower room tempered glass explosion-proof films are crafted entirely from PET transparent polyester fiber film. This material exhibits high strength, tear resistance, and high elongation, coupled with resistance to strong acids and alkalis. It maintains its physical properties even under high temperatures, ensuring durability and reliability in the demanding environment of a shower room.

Maintenance and Usage of Explosion-Proof Film

Dry Application Process: The glass film primarily utilizes a dry application method, ensuring quick and efficient adhesion. Special consideration is given to humid conditions, temperature variations, and time, gradually reducing the occurrence of water spots within two to six weeks.

Post-Installation Care: After installing glass explosion-proof film, it is advisable to refrain from cleaning or wiping the glass for the initial two days. During this period, changes in appearance are a natural part of the film's bonding process.

Surface Protection: The surface of the explosion-proof film is coated to resist scratches. With proper maintenance, the film retains its luminosity for years. Soft, clean cotton cloth and standard household glass cleaners or mildly acidic cleansers are recommended for optimal results.

In conclusion, the decision to affix an explosion-proof film to the glass door of a shower room goes beyond a mere safety precaution; it is a conscious effort to safeguard against potential hazards and ensure a secure bathing environment. By understanding the necessity, characteristics, and maintenance requirements of the explosion-proof film, consumers can make informed choices that prioritize safety without compromising the comfort and luxury of their shower experiences.

Types of Anke Explosion-Proof Film For Sale

|

| |

|

|